CNC Shape Glass Cutting - Stand Alone with Air floatation

CNC Shape Glass Cutting - Stand Alone with Air floatation

CNC Shape Glass Cutting - Stand Alone with Air floatation

CNC Shape Glass Cutting - Stand Alone with Air floatation

CNC Shape Glass Cutting - Stand Alone with Air floatation

CNC Shape Glass Cutting - Stand Alone with Air floatation

CNC Shape Glass Cutting - Stand Alone with Air floatation

CNC Shape Glass Cutting - Stand Alone with Air floatation

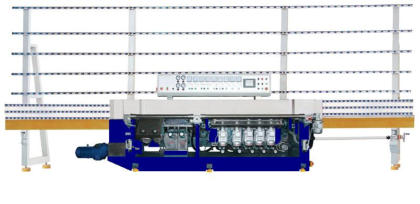

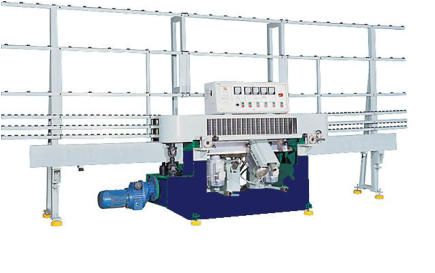

Glass Edge Mitering Machines - Straight Edge

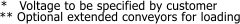

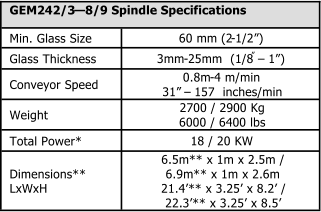

The Production Series Feature Extra heavy duty spindles and conveyor construction for polishing or mitering glass edges and is recommended

construction for polishing or mitering glass edges and is recommended for the mid to large size glass fabricator.

for the mid to large size glass fabricator. * Glass thickness up to 50mm is possible on 11 spindle model if special

ordered.

All mitering machines come with Mitsubishi PLC touch screens and are

capable of operating in automatic or manual mode.

Interface if very user friendly. It allows the operator to quickly change

* Glass thickness up to 50mm is possible on 11 spindle model if special

ordered.

All mitering machines come with Mitsubishi PLC touch screens and are

capable of operating in automatic or manual mode.

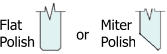

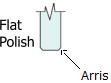

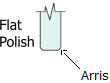

Interface if very user friendly. It allows the operator to quickly change set up between glass thickness both for flat polish and mitered edge.

set up between glass thickness both for flat polish and mitered edge.

construction for polishing or mitering glass edges and is recommended

construction for polishing or mitering glass edges and is recommended for the mid to large size glass fabricator.

for the mid to large size glass fabricator. * Glass thickness up to 50mm is possible on 11 spindle model if special

ordered.

All mitering machines come with Mitsubishi PLC touch screens and are

capable of operating in automatic or manual mode.

Interface if very user friendly. It allows the operator to quickly change

* Glass thickness up to 50mm is possible on 11 spindle model if special

ordered.

All mitering machines come with Mitsubishi PLC touch screens and are

capable of operating in automatic or manual mode.

Interface if very user friendly. It allows the operator to quickly change set up between glass thickness both for flat polish and mitered edge.

set up between glass thickness both for flat polish and mitered edge.

Shape Glass Edging Machine - Curved Edges

Glass Drilling Machines

Vertical Glass Washing Machines

Horizontal Glass Washing Machines

Glass Edge Polishing Machines - Straight Edge

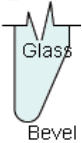

Glass Edge Bevelling Machines - Straight Edge

Glass Sandblasting Machines

Glass Edge Bevelling Machines - Straight Edge

HIGH PERFORMANCE AND AFFORDABLE GLASS MACHINERY

Actual machines may differ slightly from picture

Ho

HOme

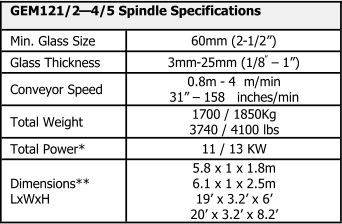

4 Spindle GEM121 Shown above. Actual machines may differ slightly from picture

GEM Glass Polishing Machines feature simple operation, great performance and are very affordable! Quick changeover from

performance and are very affordable! Quick changeover from any thickness is possible (only takes a few seconds with no

any thickness is possible (only takes a few seconds with no wheel change)! Working speed is adjustable, LED readouts for

wheel change)! Working speed is adjustable, LED readouts for conveyor speed and glass thickness. Stainless Steel tanks,

conveyor speed and glass thickness. Stainless Steel tanks, covers and working section. Spare parts package included.

covers and working section. Spare parts package included.  Comes with 1 year warranty. Low maintenance and good

Comes with 1 year warranty. Low maintenance and good performance.

performance.

performance and are very affordable! Quick changeover from

performance and are very affordable! Quick changeover from any thickness is possible (only takes a few seconds with no

any thickness is possible (only takes a few seconds with no wheel change)! Working speed is adjustable, LED readouts for

wheel change)! Working speed is adjustable, LED readouts for conveyor speed and glass thickness. Stainless Steel tanks,

conveyor speed and glass thickness. Stainless Steel tanks, covers and working section. Spare parts package included.

covers and working section. Spare parts package included.  Comes with 1 year warranty. Low maintenance and good

Comes with 1 year warranty. Low maintenance and good performance.

performance.

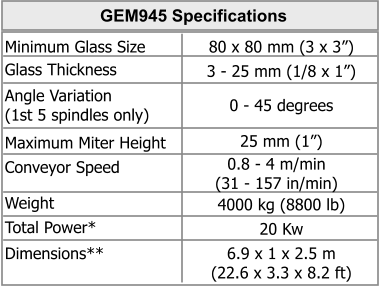

Model GEM945P (9 Spindle) -PLC Control for fast and easy setups (Other spindle configurations available)

Model GEM1045P (10 Spindle) - PLC Control for fast and easy setups

Model GEM1145P (11 Spindle) - PLC Control for fast and easy setups

Miter/Polish section [2 Diamond, 1 Resin, 1 Polish, 1 Cerium] +2 Arris Cut + 2 Arris Polish

Model GEM1445P (14 Spindle) For Awards & Recognition Market - Other configurations available

Actual machines may differ slightly from picture

This machine is designed primarily for the Gift and Recognition market to be able to miter and flat polish straight glass edges at the same time and the Conveyor

to miter and flat polish straight glass edges at the same time and the Conveyor design allows for very firm clamping of small pieces. Various wheel configurations

design allows for very firm clamping of small pieces. Various wheel configurations are possible.

are possible.

to miter and flat polish straight glass edges at the same time and the Conveyor

to miter and flat polish straight glass edges at the same time and the Conveyor design allows for very firm clamping of small pieces. Various wheel configurations

design allows for very firm clamping of small pieces. Various wheel configurations are possible.

are possible.

GEM Glass Mitering Machines feature simple operation, great performance and are very affordable! Quick changeover from

performance and are very affordable! Quick changeover from any thickness is possible (only takes a few seconds with no

any thickness is possible (only takes a few seconds with no wheel change)! Working speed is adjustable, PLC Touch screen

wheel change)! Working speed is adjustable, PLC Touch screen readout for conveyor speed and glass thickness, miter angle

readout for conveyor speed and glass thickness, miter angle and remainder edge. Stainless Steel tanks, covers and working

and remainder edge. Stainless Steel tanks, covers and working section. Spare parts package included. Comes with 1 year

section. Spare parts package included. Comes with 1 year warranty. Low maintenance and good performance.

warranty. Low maintenance and good performance.

performance and are very affordable! Quick changeover from

performance and are very affordable! Quick changeover from any thickness is possible (only takes a few seconds with no

any thickness is possible (only takes a few seconds with no wheel change)! Working speed is adjustable, PLC Touch screen

wheel change)! Working speed is adjustable, PLC Touch screen readout for conveyor speed and glass thickness, miter angle

readout for conveyor speed and glass thickness, miter angle and remainder edge. Stainless Steel tanks, covers and working

and remainder edge. Stainless Steel tanks, covers and working section. Spare parts package included. Comes with 1 year

section. Spare parts package included. Comes with 1 year warranty. Low maintenance and good performance.

warranty. Low maintenance and good performance.

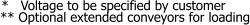

Model GEM121 (4 Spindle) - Low price, Cup style Glass polisher for small space

Model GEM411 (6 Spindle) - 2 extra spindles for better polish on flat edge

GEM121- 1 Flat Diamond, 2 Arris Cut, 1 Flat Polish

GEM411- 1 Flat Diamond, 1 Flat Resin, 2 Flat Polish, 2 Arris Cut

Actual machines may differ slightly from picture

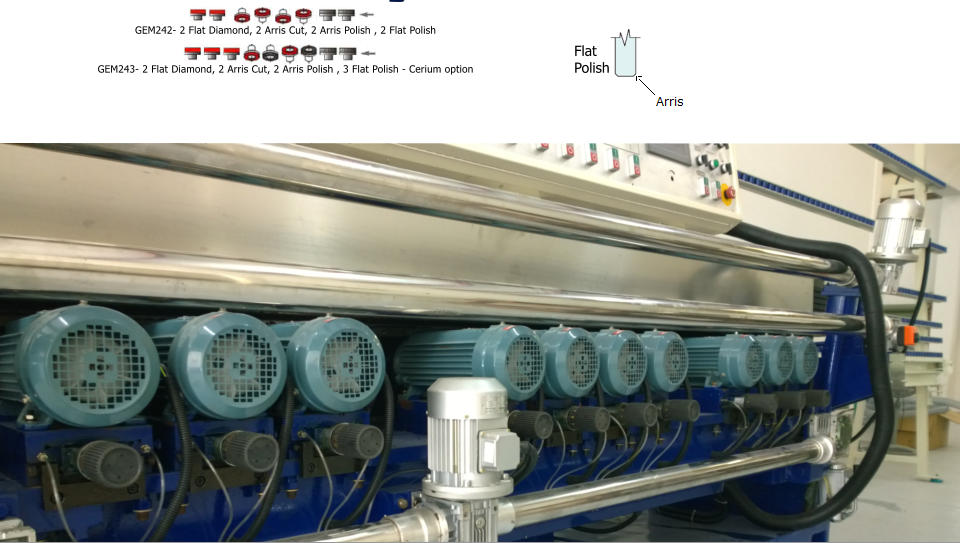

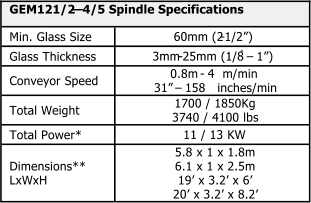

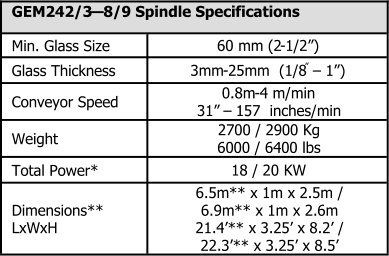

Model GEM242 (8 Spindle) Furniture grade edge polish and polished arris.

Model GEM243 (9 Spindle) Our best seller! All facets polished with cerium finish on flat side

GEM242- 2 Flat Diamond, 2 Arris Cut, 2 Arris Polish , 2 Flat Polish

GEM243- 2 Flat Diamond, 2 Arris Cut, 2 Arris Polish , 3 Flat Polish - Cerium option

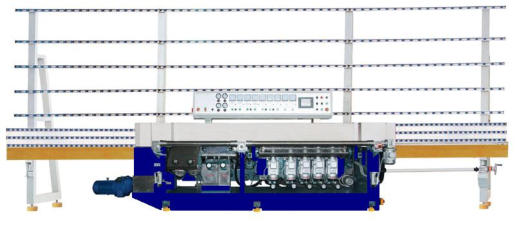

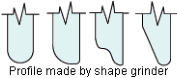

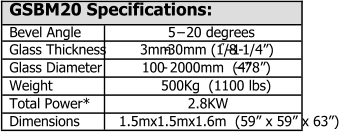

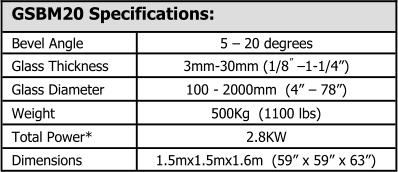

Model GSBM20 Shape Glass Edging Machine - Outer Edge Processing

-

-

Actual machine may differ slightly from picture

Actual machine may differ slightly from picture

GEM Glass Bevelling Machines feature simple operation, great performance and are very affordable! Quick changeover from any

performance and are very affordable! Quick changeover from any thickness and bevel size can be accomplished in seconds with Mistubishi

PLC touch screen control! Bevels are clear and straight with miters that

thickness and bevel size can be accomplished in seconds with Mistubishi

PLC touch screen control! Bevels are clear and straight with miters that line up in the corners. Working speed is adjustable, LED readouts for

line up in the corners. Working speed is adjustable, LED readouts for conveyor speed, glass thickness and bottom edge remainder. High

conveyor speed, glass thickness and bottom edge remainder. High quality spindles produce sharp clear and straight bevels. Stainless Steel

quality spindles produce sharp clear and straight bevels. Stainless Steel tanks, covers and working section. Spare parts package included.

tanks, covers and working section. Spare parts package included.  Comes with 1 year parts warranty. Low maintenance and great

Comes with 1 year parts warranty. Low maintenance and great performance.

performance.

performance and are very affordable! Quick changeover from any

performance and are very affordable! Quick changeover from any thickness and bevel size can be accomplished in seconds with Mistubishi

PLC touch screen control! Bevels are clear and straight with miters that

thickness and bevel size can be accomplished in seconds with Mistubishi

PLC touch screen control! Bevels are clear and straight with miters that line up in the corners. Working speed is adjustable, LED readouts for

line up in the corners. Working speed is adjustable, LED readouts for conveyor speed, glass thickness and bottom edge remainder. High

conveyor speed, glass thickness and bottom edge remainder. High quality spindles produce sharp clear and straight bevels. Stainless Steel

quality spindles produce sharp clear and straight bevels. Stainless Steel tanks, covers and working section. Spare parts package included.

tanks, covers and working section. Spare parts package included.  Comes with 1 year parts warranty. Low maintenance and great

Comes with 1 year parts warranty. Low maintenance and great performance.

performance.

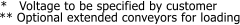

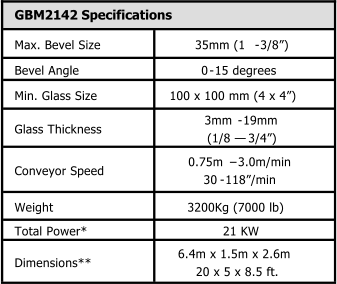

Model GBM2142P (9 Spindle) PLC Control Straight Line Glass Bevelling Machine - For small shops

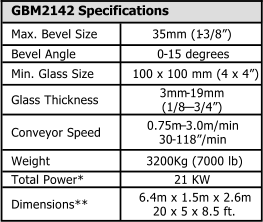

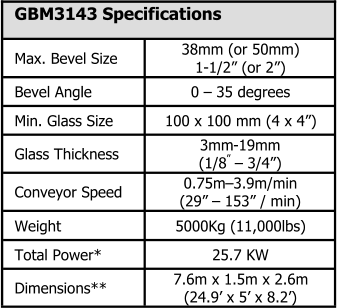

Model GBM3143P (11 Spindle) PLC Control Straight Line Glass Bevelling Machine - Production Series

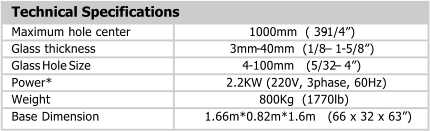

Model GDM80 Glass Drilling Machine

Serving Canada and USA since 2008

Over 30 years of Glass fabricating experience

CONTACT US

T: +1-416-342-7547

F: +1-905-492-2230

Toll Free:

F: 1-888-222-6339

PRODUCTS

© 2015 Atwood Sales Inc. All rights reserved.

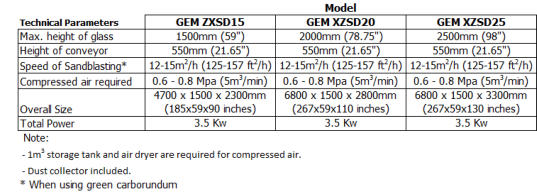

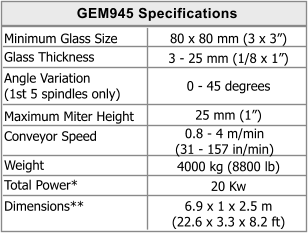

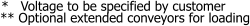

Light Duty Miter Edging Series (for small to mid size glass shops)

Production Miter Edging Series (for mid size to large fabrication glass shops)

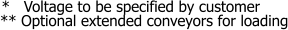

* Voltage to be specified by customer

* Voltage to be specified by customer

Features:

•

2 Opposing drill heads which produces nice clean holes

•

Automatic and Manual operating modes

•

Pneumatic clamping to hold glass while drilling

•

Laser lights for hole centering

•

Oil dampening pistons for fine tuning the drill feed rate

All Vertical Models Feature:

•

Right to left (standard) or Left to right feed

•

Stainless Steel throughout washing section

•

Powder coated where painted

•

Dryer system uses high pressure blower for excellent drying

•

Premium grade water pumps

•

Water heater for cold weather

•

Inspection Lighting on out feed conveyor

•

Simple Operator Controls

Model GEM-1600 Features:

•

Closed/Open Top Washer - Ideal for use after edging

•

Brushes: 4 Standard brushes

•

Voltage: to customer’s need

•

Power: 6 KW*

•

Max.size of original glass: 1600*2500mm (63” x 98” (Can do longer)

•

Min.size of original glass: 400*280mm (16” x 11”)

•

Thickness of original glass: 3-15 mm

•

Weight: 1500kgs (3300lbs)

•

Overall size:6200*1250*2600mm (20.34 ft. x 4.10 ft x 8.53 ft.)

Model GEM1600 - Vertical Glass Washing Machine (63” Open or Closed Top) - 4 Brush

GEM Vertical Glass Washer

Model GEM-2000 Features:

•

Closed Top Washer

•

Insulated Glass washing

grade

•

Brushes: 4 soft Low E

brushes+2 standard

brushes (retractable)

•

Voltage:to customer’s need

•

Power: 15 KW*

•

Max.size of original glass:

2000*2800mm (78” x 110”)

- longer possible

•

Min.size of original glass:

400*280mm (16” x 11”)

•

Thickness of original glass:

3-19 mm

•

Work speed: 8-48 m/min

•

Weight: 3000 kgs (6615 lbs)

•

Overall size:7500*2660*2880mm (24.6 ft. x 8.27 ft. x 9.45 ft.)

Model GEM2000 - Vertical Glass Washing Machine (78” Closed Top)

Model GEM2500 - Vertical Glass Washing Machine (98” Closed Top)

GEM Vertical Glass Washing Machine

Model GEM-2500 Features:

•

Closed Top Washer

•

Insulated Glass washing grade

•

Brushes: 4 soft Low E brushes+2 standard brushes

(retractable)

•

Voltage:to customer’s request

•

Power: 15 KW*

•

Max.size of original glass: 2500*3200mm (98” x 126”)

•

Min.size of original glass: 400*280mm (16” x 11”)

•

Thickness of original glass: 3-19 mm

•

Work speed: 8-48 m/min

•

Weight: 4000kgs (8818 lbs)

•

Overall size:9000 *2660*3380mm (29.5 x 8.3 x 11.1 ft.)

Horizontal Glass Washing Machines available in several

sizes

Feature:

•

Stainless Steel washing section

•

Direct Drive Conveyor system

•

Stainelss Steel Tanks

•

High Capacity Water pumps

•

Pre-Wash and Wash sections

•

Large blower motor for good drying mounted on

top to save space.

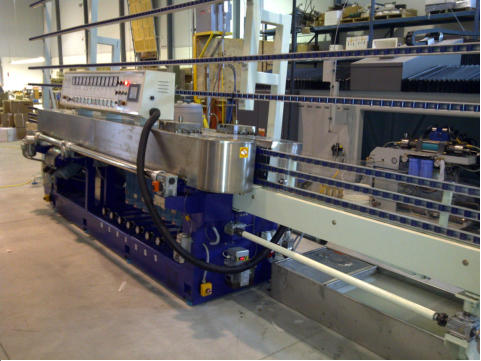

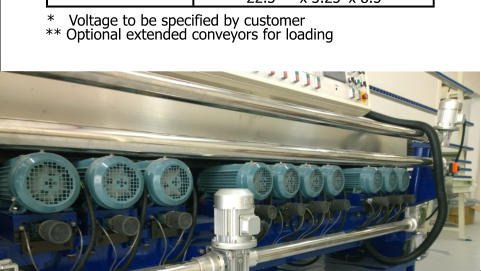

GEM1145P - Actual Installation

GEM1045P - Miter/Polish section [2 Diamond, 2 Resin, 1 Polish, 1 Cerium] +2 Arris Cut + 2 Arris Polish

GEM1145P - Miter/Polish section [2 Diamond, 2 Resin, 1 Polish, 2 Cerium] +2 Arris Cut + 2 Arris Polish

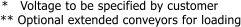

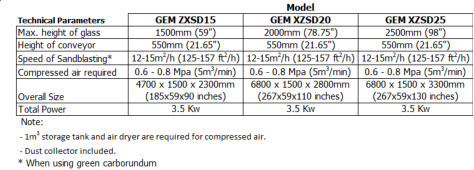

These machines are controlled by PLC, and are

suitable for processing 5-30mm thickness of flat

glass.

Glass is moved automatically by belt conveyor.

When the glass arrives to the place for

sandblasting, the guns which are belt driven will

move up-and-down while spraying out sand.

The height and the width of sandblasting can be

adjusted according to the requirements for the

order to make sandblasting more efficient.

The advantages of the belt drive are stable

transmission, high efficiency and easy

maintenance.

The drive structure of the sandblasting gun sits

outside the machine which helps preserve

longevity and reduces and simplifies

maintenance. The machine adopts PLC control,

which automates the sandblasting operation.

Note: This machine requires a separate air compressor and air tank.

A good quality 50 HP air compressor with air drying and filtering is

essential. As well an air tank supply near the sandblasting machine is

also recommended.

Description

•

This machine is designed for the grinding and polishing of exterior edges of shaped glass.

•

By changing the grinding wheel, different edge profiles (flat, pencil, OG, etc... are possible.

•

The height of the spindle is easily adjusted with a motorized control.

•

A pneumatic cylinder (included attachment) makes it possible to process circle shapes automatically.

•

The turntable drive motor and worm gear are installed in the base of the housing. The turntable speed is adjustable by a

handwheel.

GEM1145P - Actual Installation

Some of our Installations

CNC Shape Glass Cutting - Stand Alone with Air floatation

CNC Shape Glass Cutting - Stand Alone with Air floatation

CNC Shape Glass Cutting - Stand Alone with Air floatation

CNC Shape Glass Cutting - Stand Alone with Air floatation

CNC Shape Glass Cutting - Stand Alone with Air floatation

CNC Shape Glass Cutting - Stand Alone with Air floatation

CNC Shape Glass Cutting - Stand Alone with Air floatation

Glass Edge Mitering Machines - Straight Edge

The Production Series Feature Extra heavy duty spindles and conveyor construction for polishing or mitering glass edges and is recommended

construction for polishing or mitering glass edges and is recommended for the mid to large size glass fabricator.

for the mid to large size glass fabricator. * Glass thickness up to 50mm is possible on 11 spindle model if special

ordered.

All mitering machines come with Mitsubishi PLC touch screens and are

capable of operating in automatic or manual mode.

Interface if very user friendly. It allows the operator to quickly change

* Glass thickness up to 50mm is possible on 11 spindle model if special

ordered.

All mitering machines come with Mitsubishi PLC touch screens and are

capable of operating in automatic or manual mode.

Interface if very user friendly. It allows the operator to quickly change set up between glass thickness both for flat polish and mitered edge.

set up between glass thickness both for flat polish and mitered edge.

construction for polishing or mitering glass edges and is recommended

construction for polishing or mitering glass edges and is recommended for the mid to large size glass fabricator.

for the mid to large size glass fabricator. * Glass thickness up to 50mm is possible on 11 spindle model if special

ordered.

All mitering machines come with Mitsubishi PLC touch screens and are

capable of operating in automatic or manual mode.

Interface if very user friendly. It allows the operator to quickly change

* Glass thickness up to 50mm is possible on 11 spindle model if special

ordered.

All mitering machines come with Mitsubishi PLC touch screens and are

capable of operating in automatic or manual mode.

Interface if very user friendly. It allows the operator to quickly change set up between glass thickness both for flat polish and mitered edge.

set up between glass thickness both for flat polish and mitered edge.

Shape Glass Edging Machine - Curved Edges

Glass Drilling Machines

Vertical Glass Washing Machines

Horizontal Glass Washing Machines

Glass Edge Polishing Machines - Straight Edge

Glass Edge Bevelling Machines - Straight Edge

Glass Sandblasting Machines

Glass Edge Bevelling Machines - Straight Edge

HIGH PERFORMANCE AND AFFORDABLE GLASS MACHINERY

Actual machines may differ slightly from picture

Ho

HOme

4 Spindle GEM121 Shown above. Actual machines may differ slightly from picture

GEM Glass Polishing Machines feature simple operation, great performance and are very

operation, great performance and are very affordable! Quick changeover from any

affordable! Quick changeover from any thickness is possible (only takes a few seconds

thickness is possible (only takes a few seconds with no wheel change)! Working speed is

with no wheel change)! Working speed is adjustable, LED readouts for conveyor speed

adjustable, LED readouts for conveyor speed and glass thickness. Stainless Steel tanks, covers and working

and glass thickness. Stainless Steel tanks, covers and working section. Spare parts package included. Comes with 1 year

section. Spare parts package included. Comes with 1 year warranty. Low maintenance and good performance.

warranty. Low maintenance and good performance.

operation, great performance and are very

operation, great performance and are very affordable! Quick changeover from any

affordable! Quick changeover from any thickness is possible (only takes a few seconds

thickness is possible (only takes a few seconds with no wheel change)! Working speed is

with no wheel change)! Working speed is adjustable, LED readouts for conveyor speed

adjustable, LED readouts for conveyor speed and glass thickness. Stainless Steel tanks, covers and working

and glass thickness. Stainless Steel tanks, covers and working section. Spare parts package included. Comes with 1 year

section. Spare parts package included. Comes with 1 year warranty. Low maintenance and good performance.

warranty. Low maintenance and good performance.

GEM1145P - Actual Installation

Model GEM945P (9 Spindle)

PLC Control for fast and easy setups (Other spindle configurations available)

Model GEM1045P (10 Spindle) - PLC Control for fast and easy setups

Model GEM1145P (11 Spindle) - PLC Control for fast and easy setups

Miter/Polish section [2 Diamond, 1 Resin, 1 Polish, 1 Cerium] +2 Arris Cut + 2 Arris Polish

Model GEM1445P (14 Spindle)

For Awards & Recognition Market - Other configurations available

Actual machines may differ slightly from picture

This machine is designed primarily for the Gift and Recognition market to be able to miter and flat polish straight glass edges at

market to be able to miter and flat polish straight glass edges at the same time and the Conveyor design allows for very firm

the same time and the Conveyor design allows for very firm clamping of small pieces. Various wheel configurations are

clamping of small pieces. Various wheel configurations are possible.

possible.

market to be able to miter and flat polish straight glass edges at

market to be able to miter and flat polish straight glass edges at the same time and the Conveyor design allows for very firm

the same time and the Conveyor design allows for very firm clamping of small pieces. Various wheel configurations are

clamping of small pieces. Various wheel configurations are possible.

possible.

GEM Glass Mitering Machines feature simple operation, great performance and are very

operation, great performance and are very affordable! Quick changeover from any

affordable! Quick changeover from any thickness is

thickness is  possible (only takes a few seconds with no

possible (only takes a few seconds with no wheel change)! Working speed is adjustable, PLC Touch screen readout for conveyor

wheel change)! Working speed is adjustable, PLC Touch screen readout for conveyor speed and glass thickness, miter angle and remainder edge. Stainless Steel tanks,

speed and glass thickness, miter angle and remainder edge. Stainless Steel tanks, covers and working section. Spare parts package included. Comes with 1 year

covers and working section. Spare parts package included. Comes with 1 year warranty. Low maintenance and good performance.

warranty. Low maintenance and good performance.

operation, great performance and are very

operation, great performance and are very affordable! Quick changeover from any

affordable! Quick changeover from any thickness is

thickness is  possible (only takes a few seconds with no

possible (only takes a few seconds with no wheel change)! Working speed is adjustable, PLC Touch screen readout for conveyor

wheel change)! Working speed is adjustable, PLC Touch screen readout for conveyor speed and glass thickness, miter angle and remainder edge. Stainless Steel tanks,

speed and glass thickness, miter angle and remainder edge. Stainless Steel tanks, covers and working section. Spare parts package included. Comes with 1 year

covers and working section. Spare parts package included. Comes with 1 year warranty. Low maintenance and good performance.

warranty. Low maintenance and good performance.

Model GEM121

(4 Spindle) - Low price, Cup style Glass polisher for small space

Model GEM411

(6 Spindle) - 2 extra spindles for better polish on flat edge

GEM121- 1 Flat Diamond, 2 Arris Cut, 1 Flat Polish

GEM411- 1 Flat Diamond, 1 Flat Resin, 2 Flat Polish, 2 Arris Cut

Actual machines may differ slightly from picture

Model GEM242 (8 Spindle)

Furniture grade edge polish and polished arris.

Model GEM243 (9 Spindle)

Our best seller! All facets polished with cerium finish on flat side

GEM242- 2 Flat Diamond, 2 Arris Cut, 2 Arris Polish , 2 Flat Polish

GEM243- 2 Flat Diamond, 2 Arris Cut, 2 Arris Polish , 3 Flat Polish - Cerium option

Model GSBM20 Shape Glass Edging Machine - Outer Edge Processing

-

-

Actual machine may differ slightly from picture

Actual machine may differ slightly from picture

Model GBM2142P (9 Spindle)

PLC Control Straight Line Glass Bevelling Machine - For small shops

Model GBM3143P (11 Spindle)

PLC Control Straight Line Glass Bevelling Machine - Production Series

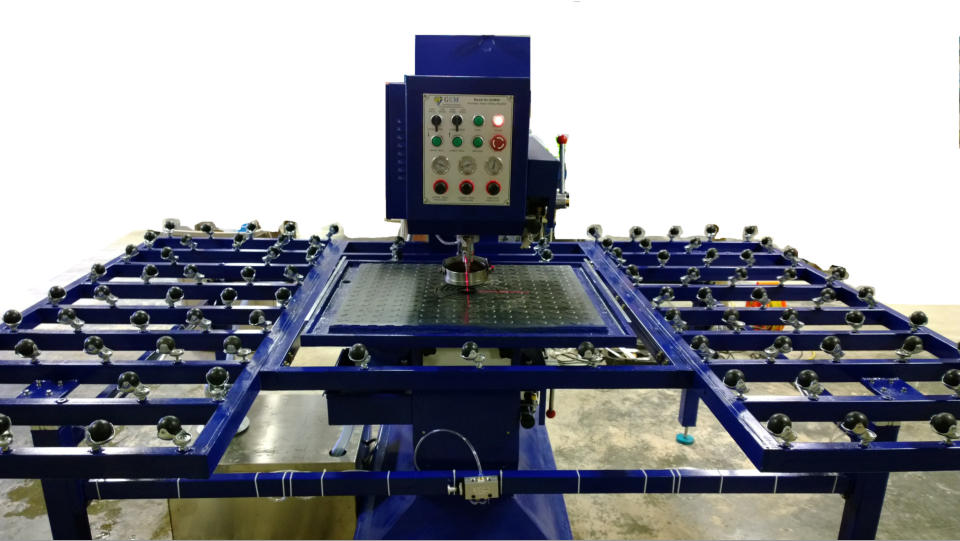

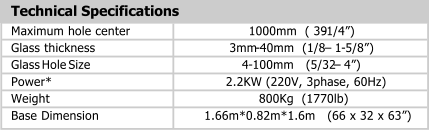

Model GDM80 Glass Drilling Machine

Light Duty Miter Edging Series (for small to mid size glass shops)

Production Miter Edging Series

(for mid size to large fabrication glass shops)

* Voltage to be specified by customer

* Voltage to be specified by customer

Features:

•

2 Opposing drill heads which produces nice clean holes

•

Automatic and Manual operating modes

•

Pneumatic clamping to hold glass while drilling

•

Laser lights for hole centering

•

Oil dampening pistons for fine tuning the drill feed rate

All Vertical Models Feature:

•

Right to left (standard) or Left to right feed

•

Stainless Steel throughout washing section

•

Powder coated where painted

•

Dryer system uses high pressure blower for excellent drying

•

Premium grade water pumps

•

Water heater for cold weather

•

Inspection Lighting on out feed conveyor

•

Simple Operator Controls

Model GEM-1600 Features:

•

Closed/Open Top Washer - Ideal for use after edging

•

Brushes: 4 Standard brushes

•

Voltage: to customer’s need

•

Power: 6 KW*

•

Max.size of original glass: 1600*2500mm (63” x 98” (Can do longer)

•

Min.size of original glass: 400*280mm (16” x 11”)

•

Thickness of original glass: 3-15 mm

•

Weight: 1500kgs (3300lbs)

•

Overall size:6200*1250*2600mm (20.34 ft. x 4.10 ft x 8.53 ft.)

Model GEM1600 - Vertical Glass Washing Machine (63” Open or Closed Top) - 4 Brush

GEM Vertical Glass Washer

Model GEM-2000 Features:

•

Closed Top Washer

•

Insulated Glass washing grade

•

Brushes: 4 soft Low E brushes+2 standard brushes (retractable)

•

Voltage:to customer’s need

•

Power: 15 KW*

•

Max.size of original glass: 2000*2800mm (78” x 110”) - longer possible

•

Min.size of original glass: 400*280mm (16” x 11”)

•

Thickness of original glass: 3-19 mm

•

Work speed: 8-48 m/min

•

Weight: 3000 kgs (6615 lbs)

•

Overall size:7500*2660*2880mm (24.6 ft. x 8.27 ft. x 9.45 ft.)

Model GEM2000 - Vertical Glass Washing Machine (78” Closed Top)

Model GEM2500 - Vertical Glass Washing Machine (98” Closed Top)

GEM Vertical Glass Washing Machine

Model GEM-2500 Features:

•

Closed Top Washer

•

Insulated Glass washing grade

•

Brushes: 4 soft Low E brushes+2 standard brushes (retractable)

•

Voltage:to customer’s request

•

Power: 15 KW*

•

Max.size of original glass: 2500*3200mm (98” x 126”)

•

Min.size of original glass: 400*280mm (16” x 11”)

•

Thickness of original glass: 3-19 mm

•

Work speed: 8-48 m/min

•

Weight: 4000kgs (8818 lbs)

•

Overall size:9000 *2660*3380mm (29.5 x 8.3 x 11.1 ft.)

Horizontal Glass Washing Machines available

in several sizes

Feature:

•

Stainless Steel washing section

•

Direct Drive Conveyor system

•

Stainelss Steel Tanks

•

High Capacity Water pumps

•

Pre-Wash and Wash sections

•

Large blower motor for good drying mounted on top to save space.

GEM1145P - Actual Installation

GEM1045P - Miter/Polish section [2 Diamond, 2 Resin, 1 Polish, 1 Cerium]

+2 Arris Cut + 2 Arris Polish

GEM1145P - Miter/Polish section [2 Diamond, 2 Resin, 1 Polish, 2 Cerium]

+2 Arris Cut + 2 Arris Polish

These machines are

controlled by PLC, and

are suitable for

processing 5-30mm

thickness of flat glass.

Glass is moved

automatically by belt

conveyor. When the

glass arrives to the

place for sandblasting,

the guns which are belt

driven will move up-

and-down while spraying out sand.

The height and the width of sandblasting can be adjusted

according to the requirements for the order to make

sandblasting more efficient.

The advantages of the belt drive are stable transmission, high

efficiency and easy maintenance.

The drive structure of the sandblasting gun sits outside the

machine which helps preserve longevity and reduces and

simplifies maintenance. The machine adopts PLC control,

which automates the sandblasting operation.

Note: This machine requires a separate air compressor and air tank. A

good quality 50 HP air compressor with air drying and filtering is

essential. As well an air tank supply near the sandblasting machine is

also recommended.

PRODUCTS

CONTACT US

T: +1-416-342-7547

F: +1-905-492-2230

Toll Free:

F: 1-888-222-6339

Serving Canada and

USA since 2008

Over 30 years of

Glass fabricating experience

GEM Glass Bevelling Machines feature simple operation, great performance and are very affordable! Quick

great performance and are very affordable! Quick changeover from any thickness and bevel size can be

changeover from any thickness and bevel size can be accomplished in seconds with Mistubishi PLC touch

accomplished in seconds with Mistubishi PLC touch screen control! Bevels are clear and straight with miters

screen control! Bevels are clear and straight with miters that line up in the corners. Working speed is adjustable,

that line up in the corners. Working speed is adjustable, LED readouts for conveyor speed, glass thickness and

LED readouts for conveyor speed, glass thickness and bottom edge remainder. High quality spindles produce

bottom edge remainder. High quality spindles produce sharp clear and straight bevels. Stainless Steel tanks,

sharp clear and straight bevels. Stainless Steel tanks, covers and working section. Spare parts package

covers and working section. Spare parts package included. Comes with 1 year parts warranty. Low maintenance and great

included. Comes with 1 year parts warranty. Low maintenance and great performance.

performance.

great performance and are very affordable! Quick

great performance and are very affordable! Quick changeover from any thickness and bevel size can be

changeover from any thickness and bevel size can be accomplished in seconds with Mistubishi PLC touch

accomplished in seconds with Mistubishi PLC touch screen control! Bevels are clear and straight with miters

screen control! Bevels are clear and straight with miters that line up in the corners. Working speed is adjustable,

that line up in the corners. Working speed is adjustable, LED readouts for conveyor speed, glass thickness and

LED readouts for conveyor speed, glass thickness and bottom edge remainder. High quality spindles produce

bottom edge remainder. High quality spindles produce sharp clear and straight bevels. Stainless Steel tanks,

sharp clear and straight bevels. Stainless Steel tanks, covers and working section. Spare parts package

covers and working section. Spare parts package included. Comes with 1 year parts warranty. Low maintenance and great

included. Comes with 1 year parts warranty. Low maintenance and great performance.

performance.

Description

•

This machine is designed for the grinding and polishing

of exterior edges of shaped glass.

•

By changing the grinding wheel, different edge profiles

(flat, pencil, OG, etc... are possible.

•

The height of the spindle is easily adjusted with a

motorized control.

•

A pneumatic cylinder (included attachment) makes it

possible to process circle shapes automatically.

•

The turntable drive motor and worm gear are installed in

the base of the housing. The turntable speed is

adjustable by a handwheel.

Mitering Machines

Polishing Machines

Bevelling Machines

Drilling Machines

Shape Edging Machines

Washing Machines

Sandblasting Machines